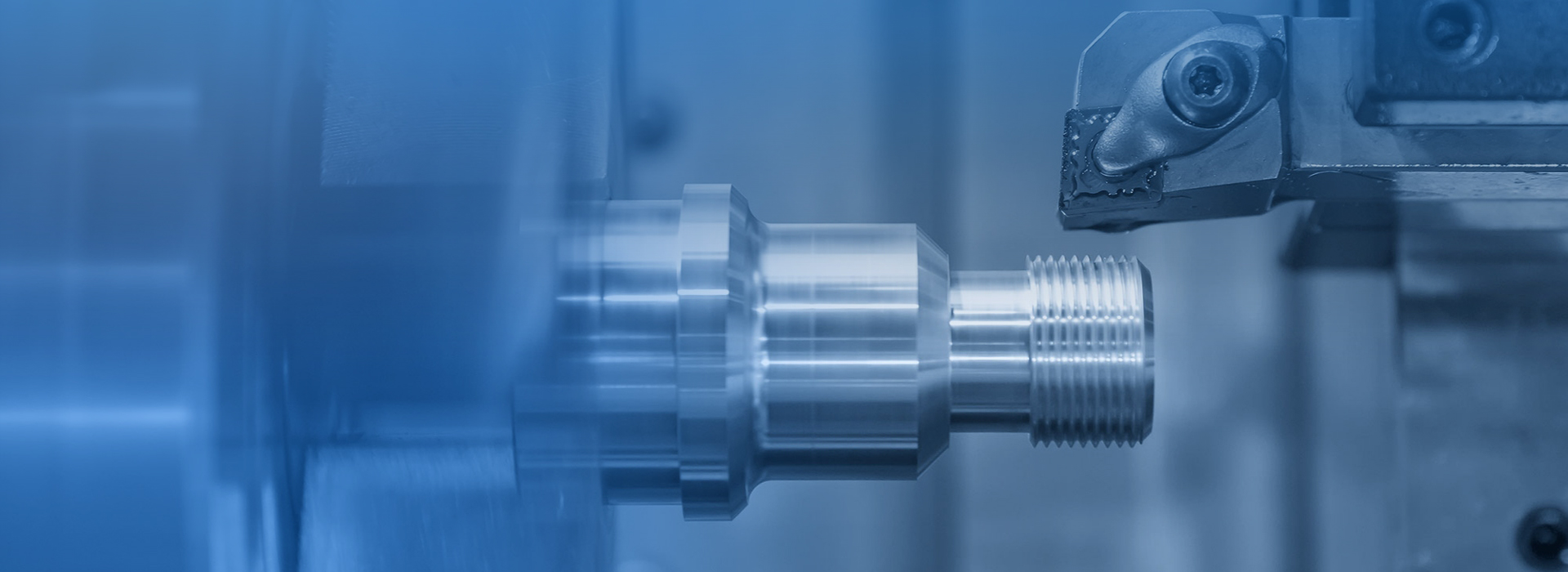

The company has obtained ISO 9001 certification and established a comprehensive quality control system.

Proficient in using the five major tools for product design and process development, with a focus on the widespread use of error prevention.

IQC, IPQC, and FQC have been established to monitor the entire process of product quality.

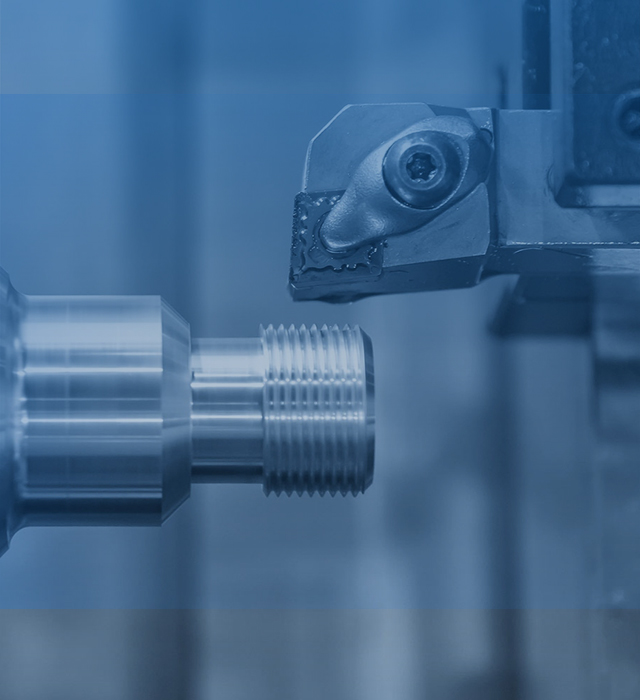

The establishment of the testing center has testing equipment such as coordinate measuring machines,

contour meters, and cylindricity meters, fully meeting the needs of product testing.

Introduce a fast response mechanism to quickly solve on-site problems;

Use control charts to control the process characteristics of key and important control points in products;

Implement hierarchical auditing to inspect and supervise the compliance of product processes.

Regularly organize product audits and special process audits to identify opportunities for improvement.

Capable of continuous improvement.